Types of Shipping Boxes and Corrugated Packaging

Explore different types of shipping boxes from Wertheimer Box. These are some of the commonly purchased box types that we manufacture. Our manufacturing practices do not limit us to these styles alone. We offer almost any corrugated packaging or shipping box type you can imagine.

We Offer These Types of Corrugated Boxes and Many More

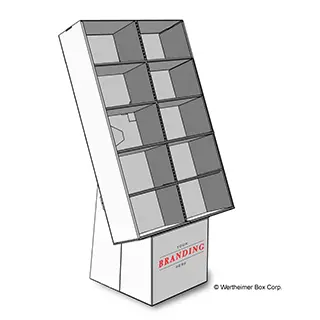

Along with our stock and custom corrugated shipping boxes and internal corrugated packaging, we offer numerous custom branded boxes personalized with your logo, complete packaging solutions, and corrugated point-of-purchase (POP) and other retail displays.

Commonly Used Types of Shipping Boxes

Click on any closed red box icon to learn more about that type of box. Close the red box when you’re finished.

Styles of Slotted Corrugated Containers

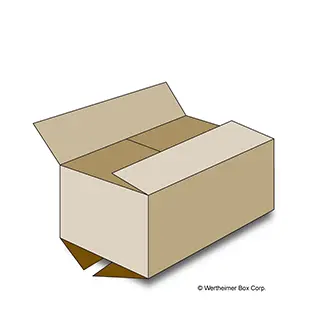

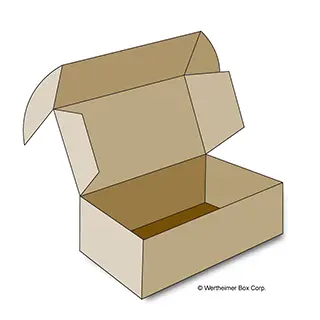

Regular Slotted Container (RSC)

Regular slotted containers (RSCs) are our most popular shipping and storage boxes.

With an RSC, one set of flaps (the outer flaps) meet in the center. You can seal your RSC with plain or branded packing tape.

Although commonly called a cardboard box, experts know that cardboard is a catch-all term. Rather, Wertheimer Box makes RSCs of corrugated fiberboard. The efficient RSC box produces minimal waste.

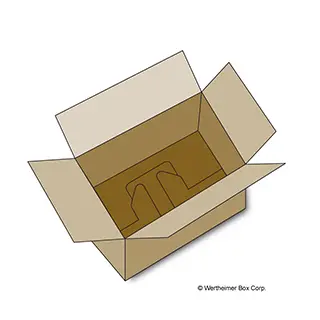

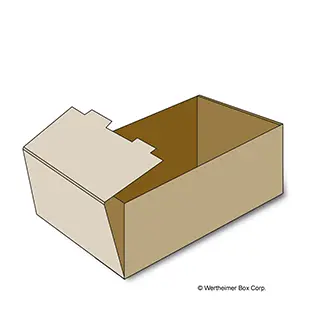

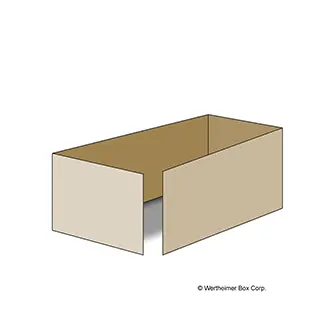

Half-Slotted Container (HSC)

A half-slotted container (HSC) has the bottom flaps of a regular slotted container (RSC). In other words, the two outer flaps meet in the center. However, the top of an HSC is open.

An HSC is versatile, efficient, and durable. It’s a great choice for traveling short distances or displaying items. Half-slotted containers are also used to collect food, clothing, toys, or other donations or to store items on a shelf.

When paired with a corrugated tray over the top as a lid, an HSC is called a telescope box.

Full Overlap Slotted Container (FOL)

A full overlap container (FOL) is a box in which the inner flaps meet in the center, and the outer flaps overlap. This makes the flaps easy to secure.

Very strong and durable, this type of construction is ideal for heavy-duty jobs, such as shipping tools, furniture, or equipment, or fragile items, such as glass, artwork, or mirrors.

An FOL container also stacks well and is resistant to rough handling. It also has additional product protection when using a knife to open the box.

Center Special Slotted Container (CSSC)

When we produce a center special slotted container (CSSC), we cut the inner and outer flaps to different lengths. This creates two layers of corrugated fiberboard on both the top and bottom of the box.

Strong, stackable, and easy to seal, CSSCs prevent someone from slicing into the product when cutting open the box. For example, these boxes may ship books, lampshades, linens, or clothing.

Snap or 1-2-3 Bottom Container With RSC Top

A snap-bottom container is also called a 1-2-3 bottom. The bottom of the container has three layers of corrugated boards that “snap” together. It’s called a 1-2-3 because it takes just three steps.

The snap bottom container enables workers to quickly construct or disassemble the box.

The RSC top is then secured with shipping tape. (See regular slotted container or RSC box.)

These boxes are commonly used for lightweight items and small quantities.

Customized UN Packaging

UN (United Nations) packaging for the transport of dangerous or hazardous materials.

Examples of Telescope Style Corrugated Boxes

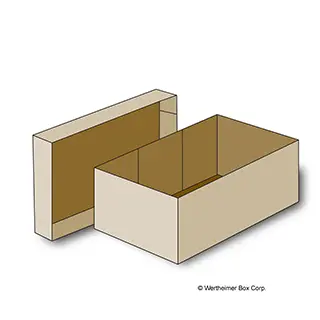

Partial Telescope Design Style Container With Cover (DSC)

A telescope container is a box with an upside-down tray as a lid. Typically, this lid covers one-third or less of the box, which makes it a partial telescope box.

The design style means that the sides are formed with stitching (staples) rather than adhesive.

These boxes make wonderful gift boxes. They can also be helpful when opening and closing the box regularly, for example, with copy paper.

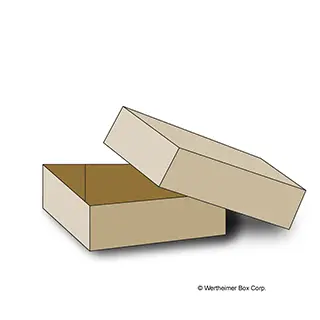

Full Telescope Design Style Container (FTD)

Like other design-style containers, this FTD has stitches (staples) at the seams for extra strength. With a full-telescope design, the two-piece box is formed from two scored and slotted blank trays.

Therefore, the box sides are contained with two full layers of corrugated, and its seams are reinforced with stitching for extra durability.

This makes a full-telescope design-style container resistant to punctures, tears, or breaks.

Don’t See the Box Type You Want? Just Ask.

We’ve illustrated some of the most popular box types. However, we offer customized corrugated shipping cartons, branded packaging solutions, proprietary ecommerce solutions, and retail displays of any color, grade, finish, or design of corrugated boards.

Types of Corrugated Folders

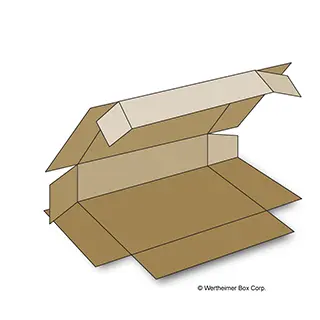

One-Piece Corrugated Folder (OPF)

One-piece corrugated folder boxes are designed to be stored flat and quickly assembled to ship items. We score the folder box, so it is simple to construct along the fold lines, and its protruding ends tuck into each side for secure locking.

Besides being easy to assemble, an OPF can ship books, artwork, and promo items. It’s commonly used to ship small, flat items in ecommerce.

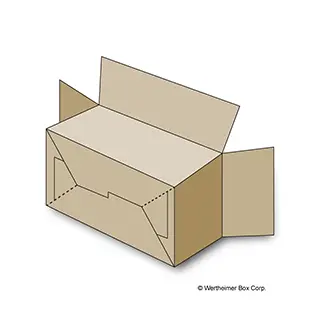

Five Piece Corrugated Folder (FPF)

The five-panel corrugated folder has a fifth panel that tucks in securely to close the box. This construction results in additional support on both ends.

Because of this extra durability, the five-piece folder is often used to ship long, flat, or narrow items, such as golf clubs or fishing poles.

Packaging Considerations

It’s not “just a box.” Read these “15 Most Frequent Packaging Mistakes.” You’ll learn how your packaging decisions can impact your product, your customer’s experience, and more.

Die-Cut Style Corrugated Trays

Roll-End Corrugated Tray With Walker Lock Ends

Roll-end trays don’t require glue or stitching (staples). A walker-lock corrugated tray has tabs and slots. The tabs tuck into the slots to lock themselves in place.

These boxes are commonly used by the food and beverage industry, electronics companies, and online stores.

Roll-End Corrugated Tray With Locking Cover

This type of tray has sides that tuck into the box to lock themselves in place.

Pre-Glued Style Corrugated Boxes and Trays

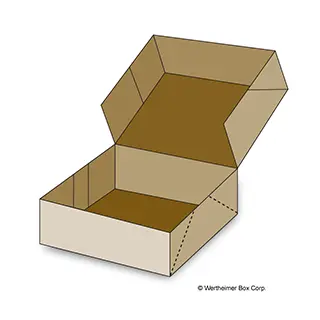

Pre-Glued Auto Bottom Corrugated Box With RSC Top Flaps

Pre-glued auto-bottom boxes save assembly time. They are often used in shipping, storage, retail, and ecommerce.

RSC flaps have two sides (outer flaps) that meet in the center and are sealed with packing tape

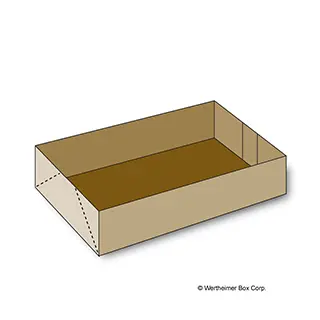

Four-Corner Corrugated Tray

They can be used as trays or as lids on telescoping boxes.

They are also used for items that need to be displayed or easily accessed. Therefore, they are often used in the food and beverage industry.

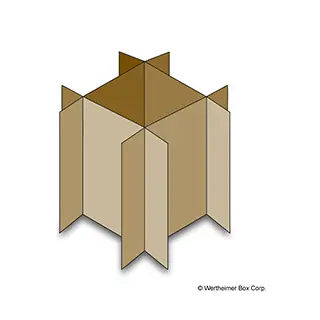

Six-Corner Corrugated Tray

The six-corner tray has six pre-glued corners, which saves assembly time.

These versatile boxes are often used to package and ship food and beverages, clothing, home goods, and more.

Types of Interior Corrugated Packaging Used in Shipping Boxes

Corrugated Pads

Corrugated pads make boxes sturdier and more rigid, so they can absorb shock. They also prevent moisture and keep items cleaner.

Each single-wall corrugated pad has three layers: a liner board, a fluted center, and another liner board.

Additionally, we manufacture double- or triple-wall pads for extra-heavy-duty jobs.

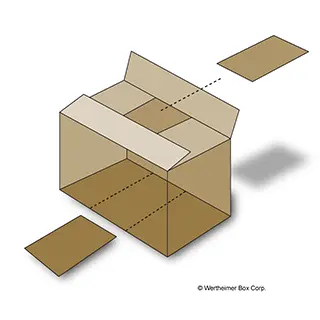

Corrugated Tube (Liner)

Corrugated tubes do.

We score the rectangle, the fold it or tape it, so it encircles the four sides of your box for added strength and rigidity.

Placed inside a box, the liner reinforces the container’s sidewalls.

Corrugated Partition

For example, they may be used to cushion large glass bottles, such as wine, beer, or liquor bottles.

Used in combination with corrugated pads, partitions may separate and protect shorter glass bottles, such as pickle jars, salad dressing bottles, or other condiments.

Want More Information?

Whether you simply have questions or you’d like an estimate, we’re here to serve you.

Wertheimer Box Offerings

Get In Touch

Wertheimer Box Corp.

Location

7950 Joliet Rd #100

McCook, IL 60525

Corporate Hours

8:00 am - 5 pm (M-F)