Shipping bags or boxes? Which one offers the greatest advantage for your product? Before you decide, you may want to weigh these five packaging considerations:

Packaging Consideration #1: Environmental Sustainability

Last month we published an in-depth article about the overall sustainability of poly bag mailers vs. corrugated boxes. Poly bags, poly bag mailers, or polyethylene (or PE) are synonymous. They are sturdy plastic shipping bags. Some contain bubble-lined interiors; others consist of woven polyethylene fibers.

When it comes to the environment, corrugated boxes are the clear winner, according to environmental experts. Moreover, responsible corrugated packaging manufacturers, such as Wertheimer Box Corp., take additional measures to prioritize environmental sustainability.

Packaging Consideration# 2: Product Protection

Product protection is arguably the most critical packaging consideration. Safety and protection throughout manufacturing, packaging, shipping, and delivery of your products are high priority consideration.

Choose packaging that will keep your products safe throughout their journey—from the first step in the manufacturing process to the end-user.

Consider Corrugated Box Protection

Foremost, corrugated box designers customize your shipping boxes to protect your products.

For example, we consider your product’s features. We examine its weight, size, overall shape, and whether it has sharp edges or protrusions. In addition, we find out whether the product will ship individually or with other identical or complementary products.

We also consider shipping laws, your freight carrier, pallet configuration, manufacturing process, and more. Learn more about many factors that impact our packaging designs.

Considering the product’s features, manufacturing, and logistics, we help ensure our clients’ products arrive undamaged at their final destination.

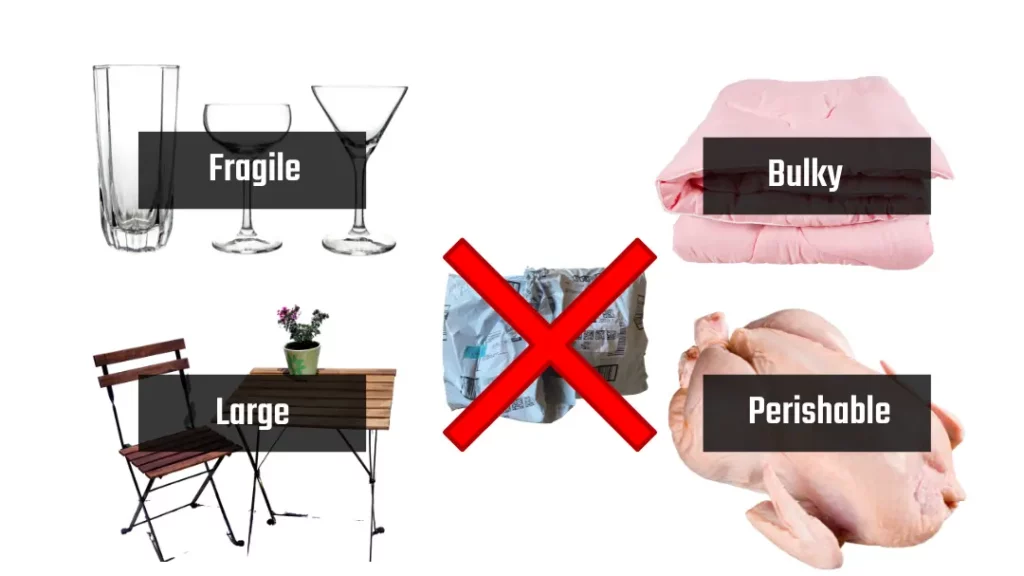

Furthermore, most products can ship safely in the appropriate corrugated box. For example, our clients choose corrugated boxes for items as fragile as figurines, breakable as bottles, and jagged as bread knives. Similarly, heavy and bulky items (e.g., refrigerators, washers, dryers, gaming machines, and more) ship in our corrugated boxes.

Likewise, perishables such as frozen, refrigerated, and shelf-ready foods ship safely in our corrugated boxes. Packaging food safety is one of our priorities. We consider it both a moral and ethical obligation.

Consider Poly Bag Mailer Protection

On the other hand, few products can arrive safely in a poly bag mailer.

If you can tolerate environmental concerns, clothing, thin fabrics, or tiny, unbreakable items can often ship in a poly bag mailer.

If the item is too large, processing machines may tear the plastic poly bag and its contents in the shipping process. For example, when shipping items First Class through the post office, your total package weight cannot exceed 13 oz.

If the product does not arrive safely, your customer may never again order from you.

Likewise, strong adhesives may make it difficult to open the bag. Your end-user may use scissors, increasing the risk of unintentionally slicing clothing.

Similarly, evaluate logistical concerns. For example, will the items need to stack on a pallet?

Packaging Consideration #3: Package Presentation and Consumer Experience

If your products, such as clothing, are going to a consumer, what is the customer experience when it arrives?

For example, most educated consumers know that plastics are not recyclable. So, they may feel guilty about throwing the shipping bag into their kitchen garbage. Or they may think less of your company.

Often, they will struggle against the strong adhesive used to seal the bag.

On the other hand, consumers may delight in the prospect of opening a box. Unveiling its contents can feel like a gift—even when they order items for themselves!

By contrast, plastic bags have a different feel. They lack the cachet of boxes. As a result, poly bag mailers can feel cheap.

Poly bags are the stuff of dog waste collection, old bread wrappers, and childhood newspapers unceremoniously tossed onto driveways.

Your products may present a more luxurious impression when mailed in a box—particularly if that box highlights creative brand colors and messages.

Therefore, product presentation and the end-user experience are important packaging considerations.

Packaging Consideration #4: Branded Messages

You can purchase custom poly bag mailers with branded messages outside—although few companies do. “Inside” printing, if it were available, would add no value.

By contrast, our machines can custom print on small or large boxes. What’s more, we can print on the inside bottom and/or side panels, the outside panels, or both. We even have machines that quickly print on both the inside and outside of your packaging—simultaneously.

Some companies prefer to showcase branding only on the inside of their boxes. Some choose inside printing to create the element of surprise for the recipient. Others prefer a box with printing only on the inside to reduce the threat of theft from porches and front doors.

With various colors of corrugated boards and inside-outside printing, your branding options are more plentiful when printing on corrugated. A bonus: all our printing inks are water-based.

Branding is an important packaging consideration.

Packaging Consideration #5: Cost of Goods Sold

Sellers of poly bag mailers claim their plastic bags are a less expensive alternative because they may be lighter and ship more cheaply.

You can calculate the cost of goods sold using the following formula:

Product Materials + Manufacturing + Packaging + Shipping

Additionally, you may need to place poly bags inside corrugated boxes, increasing your packaging costs.

We propose that other packaging considerations, such as brand reputation, safe delivery, and consumer impressions, can also determine profitability.

With plastics, the costs to the environment and your brand reputation may be expensive.

Summary: Five Packaging Considerations

Besides the cost of goods sold, consider the overall impact of poly bag mailers vs. corrugated boxes:

- Real environmental impact

- Safe product shipping and delivery

- Branding capabilities

- Company reputation

- Presentation and consumer experience

Doug Wertheimer

Get More Industry News Like This

Welcome to the Wertheimer Family! We'd like to keep you up to date with industry changes and news. Subscribe to receive our occasional news, updates and articles direct to your in-box.