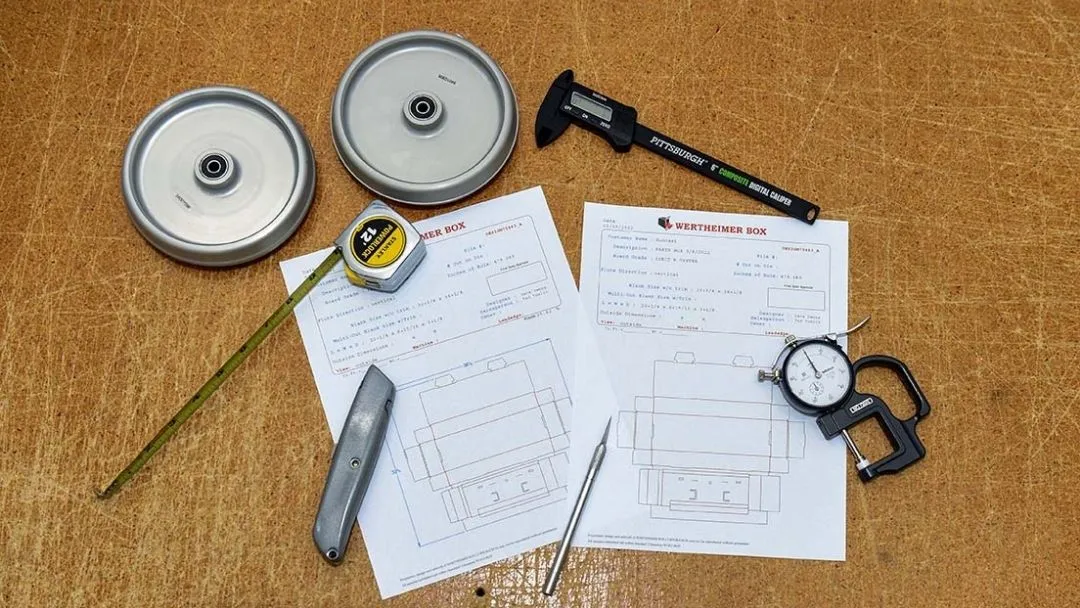

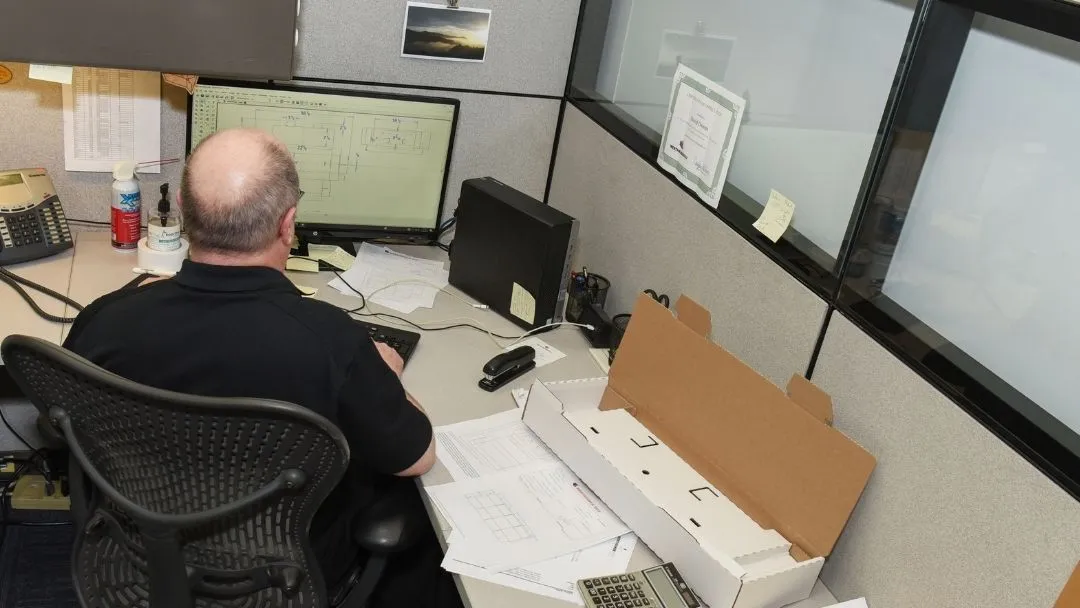

One of our structural designers, Dave Owens, discusses five facts that he and his colleagues want to know when creating your corrugated box design. Here’s what he said about what helps the box design team work quickly, efficiently, and cost-effectively.

Corrugated Box Design Fact 1: We wish we knew…

If you provided all the products going into the corrugated box we’re designing.

Please provide the number of products going into the corrugated box or retail display that we’re designing.

In other words, when you have multiple bottles, jars, chipboard (cardboard) boxes, etc., that you want to ship in one package, we can speed up the box’s design by having samples of all the items that will go into that one box, container, or display.

For example, if you have 12 bottles of ketchup going into a shipping box, it’s helpful to provide all 12 bottles. Then, we can more readily design a corrugated box with dividers or partitions to protect each item in production, storage, and shipping.

Having all the items:

- Ensures quicker accuracy of our measurements and computerized design, so everything lays out perfectly.

- Speeds up the box design process so we can manufacture your corrugated shipping boxes and/or box dividers more quickly.

Corrugated Box Design Fact 2: We wish we knew…

If this is the complete product that will go into the packaging we’re designing.

Please provide the entire product going into the box we’re designing.

Box design for multiple product components

If the product has multiple components, provide all the pieces. For example, if your product will sit in a charger and have a cord, provide the charging station and the cord.

Box design for prototypes

Or, if you have a prototype that’s not final, it would be a mistake NOT to involve your Wertheimer Box sales rep, but it may be premature to design your box.

For example, we once designed a box and were later told a valve would be sticking out of one side. So, of course, the packaging design needed to be rebuilt.

Box design for a product that you’re updating

Likewise, if the product components will soon change (e.g., you’re adding a piece, removing a part, changing a portion), let us know and provide that piece.

Corrugated Box Design Fact 3: We wish we knew…

Your expectations for packing materials.

Having all the components of your product is helpful. But we also want to know your preferences and expectations for packing materials.

Perhaps you have a high-end or luxury product that you don’t want to bury in peanuts or bubble wrap. Or maybe environmental sustainability is an essential value of your company, and you recognize that most curbside recycling doesn’t collect foam. On the other hand, perhaps cost-effectiveness is your most important value. Let us know.

In these ways, we can determine the best box design for your product and the best way to create the packaging that will house it safely within the corrugated shipping box.

We analyze hundreds of variables when we design your box.

We consider apparent factors like your product’s weight, structure, and fragility. These can help determine how the packaging design can help protect your product during assembly, storage, and shipping. For example, is it made of steel, plastic, or glass? How durable is it? Is it thin or thick?

In other words, perhaps your corrugated box requires a specific design to keep your product safe. Or maybe it will need a particular type of packing material.

Among many other types of packing materials that we may recommend, options could include:

- Shredded kraft or crinkle-cut paper

- Foam peanuts

- Bubble wrap or air pillows

- Corrugated dividers or inserts

- Foam

- Molded pulp

Of course, other factors will enter into your box design considerations. We’ll work to incorporate your values and protect your products.

Corrugated Box Design Fact 4: We wish we knew…

The trucking company (or companies) you prefer.

Please tell us the trucking companies that you prefer. We’ll want to determine the best pallet configuration for your product. For example, is a 2×6 configuration best? Or a 3×4?

Are you shipping via FedEx, UPS, or USPS? Have you come to dislike one of these transportation companies? These factors will also impact your box design, pallet configuration, and the packaging material we use inside your box.

Corrugated Box Design Fact 5: We wish we knew…

What your manufacturing operations look like.

Please invite us to visit your operation before designing your packaging. Allowing us to observe your assembly line and how you manufacture, move, and store your products can be immensely helpful.

- We’ll see how you pack your products. In that way, we can design the corrugated box in keeping with your processes. For example, will your workers or machines wind an electric cord and secure it with a zip tie? Or is the cord wound around the product, like a vacuum cleaner cord?

- Moreover, we can often recommend process improvements. For instance, recently, we recommended removing a taping step in a customer’s packing process. As a result, the new box design sped up our customer’s packing time. This faster time allowed our customer to increase profits by 23% and simultaneously decrease its packing materials costs.

- We’ll understand how your products are stored, moved, and shipped. Are they on a racking system? Are your boxes moved with a forklift? (Some forklifts may squeeze products.) These factors also impact your box design.

- We’ll look at how your products are palletized. We can see its impact on your box design and pallet configuration.

Summary

In summary, provide all the product information you can.

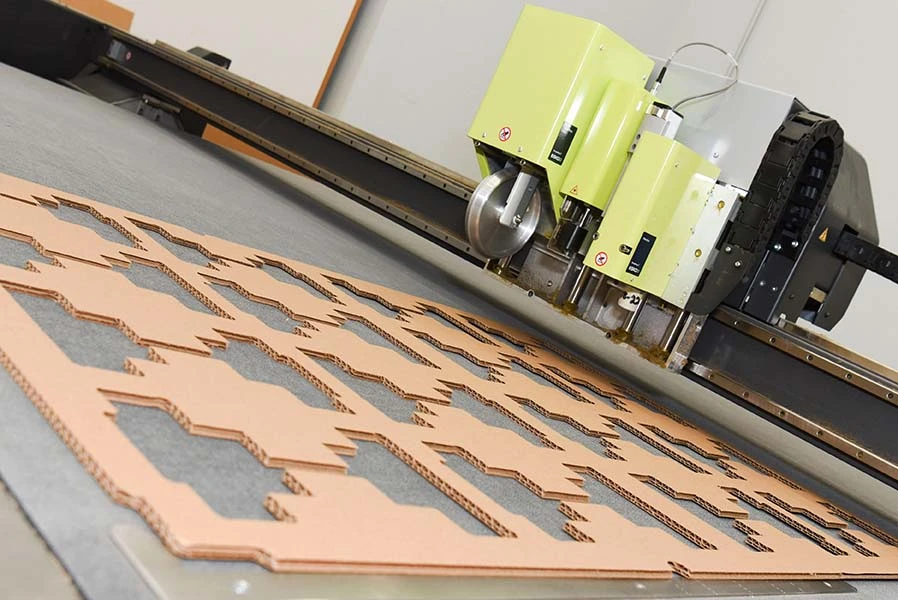

Each box design project has its own set of variables that allows our graphic and structural box designers to customize your corrugated shipping boxes, branded boxes with logos, or corrugated retail displays.

We’ve designed boxes as small as a key chain with a cube size charm to as large as an unassembled, battery-operated security car. What’s more, the types of boxes and displays that we can manufacture are nearly limitless.

Conclusion

When our customers provide all the information our sales reps and structural designers need, we can quickly, efficiently, and cost-effectively create an optimal design. As a result, we can build a better box.

Dave Owens

Get More Industry News Like This

Welcome to the Wertheimer Family! We'd like to keep you up to date with industry changes and news. Subscribe to receive our occasional news, updates and articles direct to your in-box.